- 0086-0319-5236318

- 0086-+ 86-18832961559

- reta@greatcitygroup.com

- Wechat:18832961559

| Diameter of wire: | |

|---|---|

| Machine Type: | |

| Material: | |

| Applicable wire: | |

| Control system: | |

| Availability: | |

| Quantity: | |

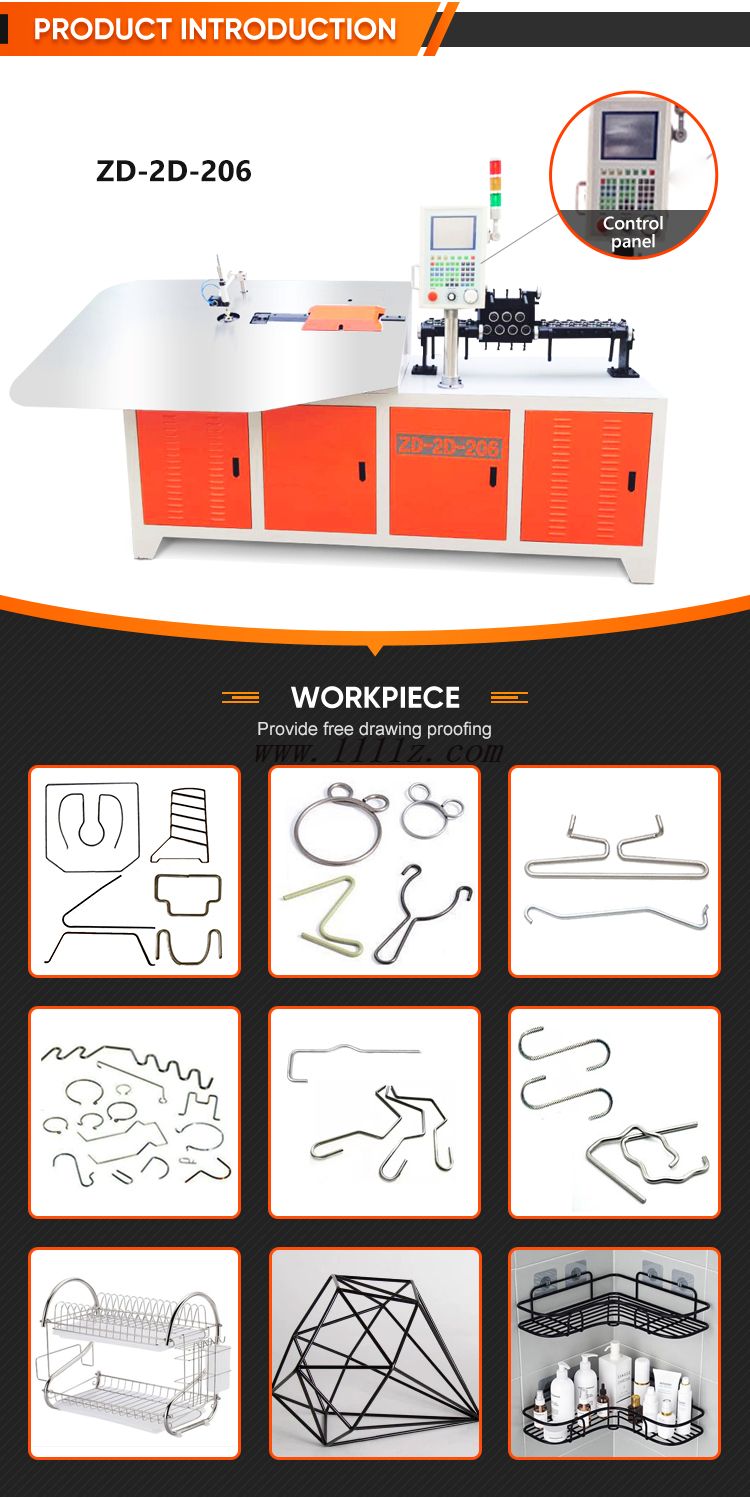

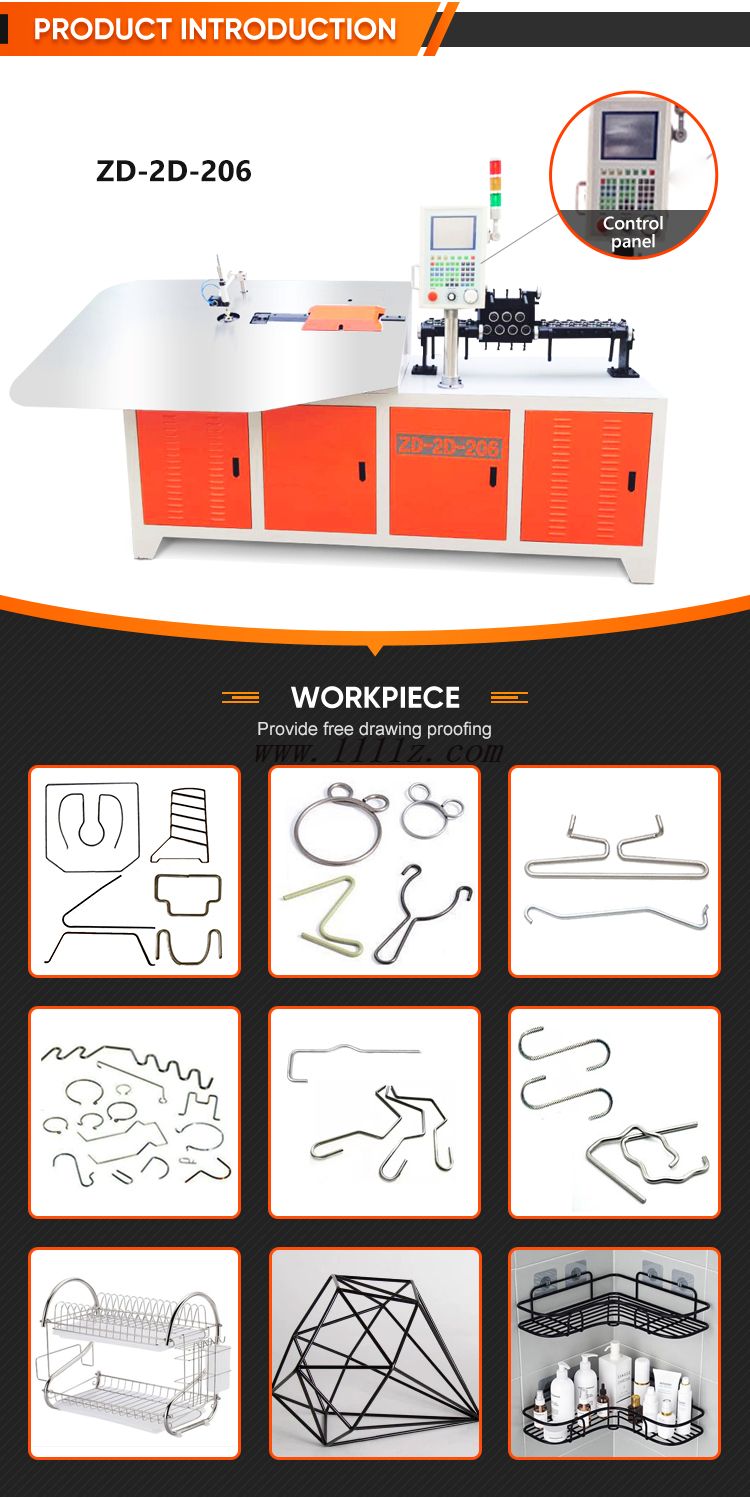

ZD-2D-206

zhongde machinery

8463300000

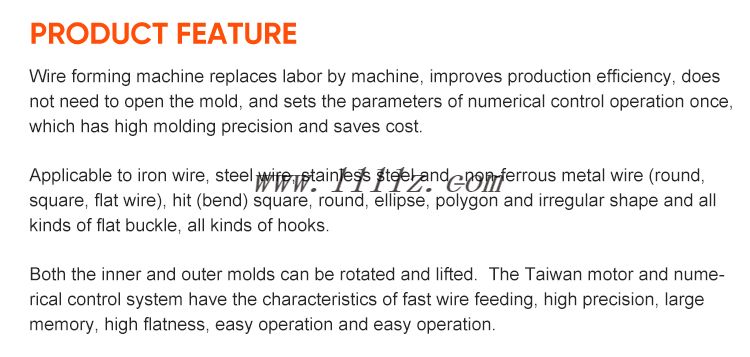

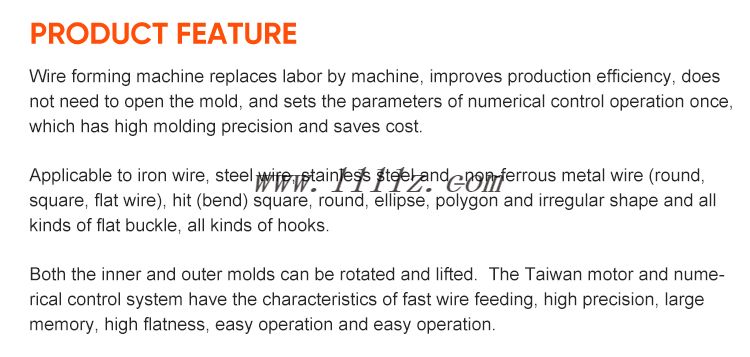

2d cnc automactic wire bending machine is to produce kinds of 2D wire forms expertly with high precision and fast speed. Adopts brand servo motor and screen display with top controller.

Advantages & Feature:

1. The error of full servo motor is smaller, the bending efficiency is higher, and the error is smaller than that of similar products of hydraulic press.

2. CNC operation is simpler and easier to learn than the same type of PLC products. Generally, the simple program can be edited by oneself within half an hour with elementary school education.

3. Because all the servo motors are used, there will be no hydraulic failure, the failure rate is lower, the scrubbing is more convenient, and the pollution caused by oil pollution will not occur.

spiral reinforcing flat steel bar bender automatic rebar bending machine Application field :

1)Auto Industry area

2)Metal wire industry

3)Display table and cargo shelf

4)Furniture and Kitchen

5)Hardware industry

6)Mattress, Sofa spring area

7)Architecture area

8)Hardware Artcraft

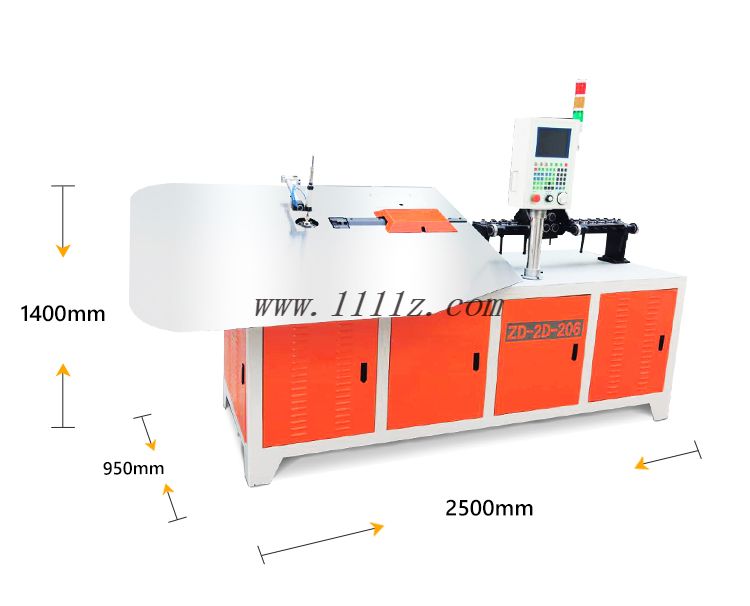

ZD-2D-206 model spiral reinforcing flat steel bar bender automatic rebar bending machine technical specification:

Model | ZD-2D-6206 |

number of axles | 3 |

processing wire dameter range | 2-6mm (iron wire ) |

Number of feeder wheels (group) | 3 |

Applicable wire | Round wire, flat wire square wire (suitable for any wire material) |

Storage | 10,000 data, 300 actions in a group |

minimum feeding speed(m/min) | 100 |

Servo motor power of feeding shaft(kW) | 2.5 |

Power of Servomotor for Cutter Shaft(kW) | 1.8 |

Power of Folded Axis Servomotor(kW) | 1.0 |

Direction of action | Internal and external die can be lifted and bended in both directions. |

Feeding accuracy(mm) | ±0.1 |

minimum bending speed | 800rmp/min,angle±180º |

Capacity | 20-24pcs/min,(200*200mm square shape) |

operating system | 32-bit Chinese and English (with upload and download function) |

Input power supply | 380V,50HZ/60HZ |

weight (KG) | 600 |

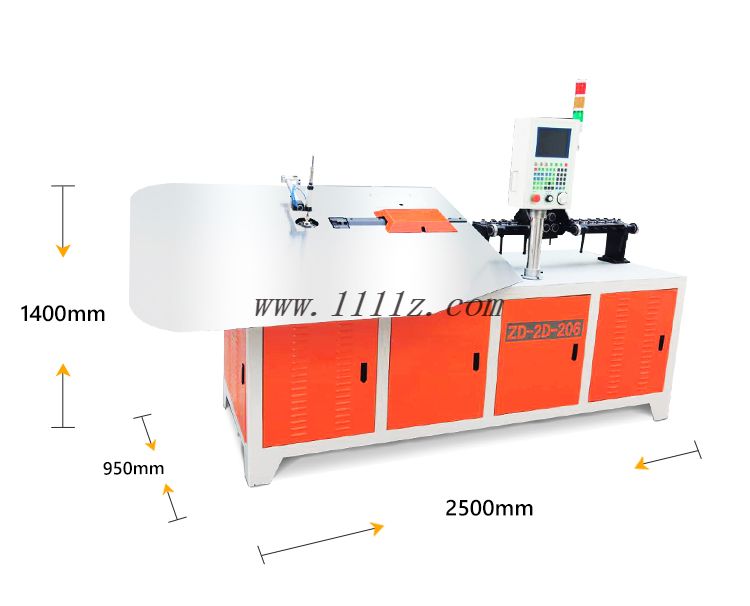

Dimension (length*width*height mm) | 2000×950×1800 |

spiral reinforcing flat steel bar bender automatic rebar bending machine video link on youtube :

https://www.youtube.com/embed/eeFWDMDSQjc?si=97KvVO0vICSzl9aa

♦Pre-sale Service

Quality & Price is built on each transaction's satisfaction

Customized Design spiral reinforcing flat steel bar bender automatic rebar bending machine based on your request,our team's hard research & existing project proposal

♦Sale Service

Strict QC Inspection---8-Level Quality Assurance System off the production line

Details & Video Sent to help your workers know how the device works

OEM&ODM Service with Professional R&D and Design Team

♦After-Sales Service

Maintenance Response in 24 hours After-Sales Service Team

Oversea Technical Support Experience

Customer Reviews Satisfaction is nearly 100%

The process shapes of automatic spiral reinforcing flat steel bar bender automatic rebar bending machine

Our machine could process 500 kinds shapes

Main accessories of wire bending machine

Wire Bending Machine CNC

Packaging

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

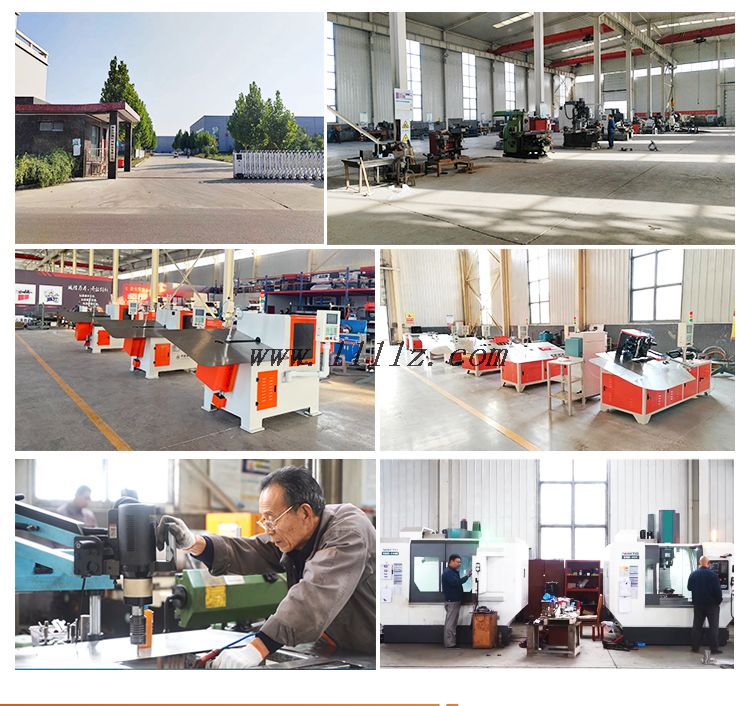

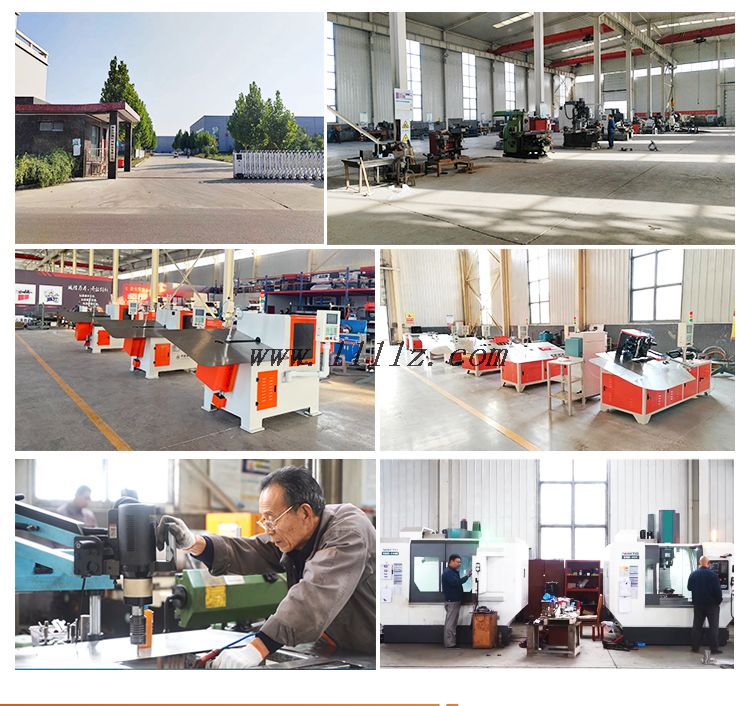

Actually, we are not a trade company, but we are business developers, we are manufacturer. We produce the machine according to customer's special requirement, it is tailor-made style. so, we aim to support the foreign companies to get high quality spiral reinforcing flat steel bar bender automatic rebar bending machine with very competitive price from Chinese market smoothly by flexible & fixed steps with the cheapest cost & the most effective way.

2d cnc automactic wire bending machine is to produce kinds of 2D wire forms expertly with high precision and fast speed. Adopts brand servo motor and screen display with top controller.

Advantages & Feature:

1. The error of full servo motor is smaller, the bending efficiency is higher, and the error is smaller than that of similar products of hydraulic press.

2. CNC operation is simpler and easier to learn than the same type of PLC products. Generally, the simple program can be edited by oneself within half an hour with elementary school education.

3. Because all the servo motors are used, there will be no hydraulic failure, the failure rate is lower, the scrubbing is more convenient, and the pollution caused by oil pollution will not occur.

spiral reinforcing flat steel bar bender automatic rebar bending machine Application field :

1)Auto Industry area

2)Metal wire industry

3)Display table and cargo shelf

4)Furniture and Kitchen

5)Hardware industry

6)Mattress, Sofa spring area

7)Architecture area

8)Hardware Artcraft

ZD-2D-206 model spiral reinforcing flat steel bar bender automatic rebar bending machine technical specification:

Model | ZD-2D-6206 |

number of axles | 3 |

processing wire dameter range | 2-6mm (iron wire ) |

Number of feeder wheels (group) | 3 |

Applicable wire | Round wire, flat wire square wire (suitable for any wire material) |

Storage | 10,000 data, 300 actions in a group |

minimum feeding speed(m/min) | 100 |

Servo motor power of feeding shaft(kW) | 2.5 |

Power of Servomotor for Cutter Shaft(kW) | 1.8 |

Power of Folded Axis Servomotor(kW) | 1.0 |

Direction of action | Internal and external die can be lifted and bended in both directions. |

Feeding accuracy(mm) | ±0.1 |

minimum bending speed | 800rmp/min,angle±180º |

Capacity | 20-24pcs/min,(200*200mm square shape) |

operating system | 32-bit Chinese and English (with upload and download function) |

Input power supply | 380V,50HZ/60HZ |

weight (KG) | 600 |

Dimension (length*width*height mm) | 2000×950×1800 |

spiral reinforcing flat steel bar bender automatic rebar bending machine video link on youtube :

https://www.youtube.com/embed/eeFWDMDSQjc?si=97KvVO0vICSzl9aa

♦Pre-sale Service

Quality & Price is built on each transaction's satisfaction

Customized Design spiral reinforcing flat steel bar bender automatic rebar bending machine based on your request,our team's hard research & existing project proposal

♦Sale Service

Strict QC Inspection---8-Level Quality Assurance System off the production line

Details & Video Sent to help your workers know how the device works

OEM&ODM Service with Professional R&D and Design Team

♦After-Sales Service

Maintenance Response in 24 hours After-Sales Service Team

Oversea Technical Support Experience

Customer Reviews Satisfaction is nearly 100%

The process shapes of automatic spiral reinforcing flat steel bar bender automatic rebar bending machine

Our machine could process 500 kinds shapes

Main accessories of wire bending machine

Wire Bending Machine CNC

Packaging

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

Actually, we are not a trade company, but we are business developers, we are manufacturer. We produce the machine according to customer's special requirement, it is tailor-made style. so, we aim to support the foreign companies to get high quality spiral reinforcing flat steel bar bender automatic rebar bending machine with very competitive price from Chinese market smoothly by flexible & fixed steps with the cheapest cost & the most effective way.

| | Address: Qiaodong District, Xingtai City,Hebei Province.China |

| | Custom Support & Sale: +86-18832961559 |

| | Working Time: Mon–Sat: 08:00–18:00 |

| | E-mail: reta@greatcitygroup.com |